Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

china sheet metal fabrication supplier

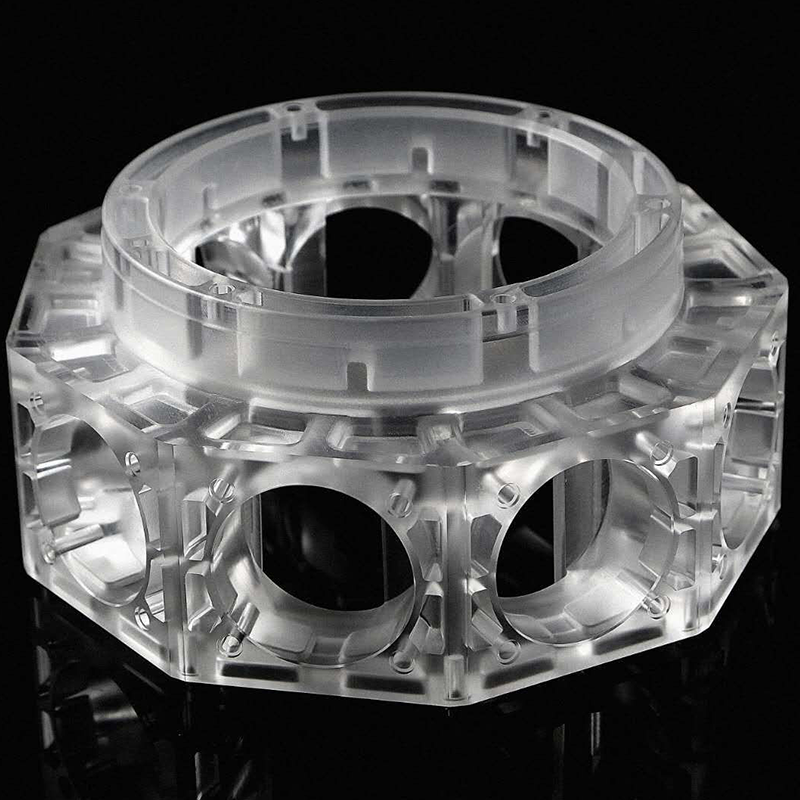

Plastic Injection Moulding Service

Plastic Injection Moulding is a cutting-edge solution designed to transform your manufacturing operations. With precision and efficiency at its core, this innovative technique allows you to create high-quality plastic products with utmost ease. Whether you're a small business or a large-scale manufacturer, Plastic Injection Moulding empowers you to streamline your production, reduce costs, and deliver exceptional results.

Overmolding

The overmolding process involves molding one plastic material over another. This ensures a seamless combination of multiple plastic parts to give a uniform and durable product. Insert molding and multi-shot molding processes help combine materials for functional and aesthetic purposes. Future Parts’s plastic injection overmolding uses these processes to ensure every component meets industrial standards.

Vacuum Casting

Vacuum casting, also known as urethane casting, blends silicone molds and 3D printed master patterns to produce short-run, rigid parts with production-level precision. Utilizing thermoplastic polyurethane within silicon or epoxy molds, the process replicates the shapes of the original master models. Final dimensions depend on the master model, part geometry, and chosen materials.

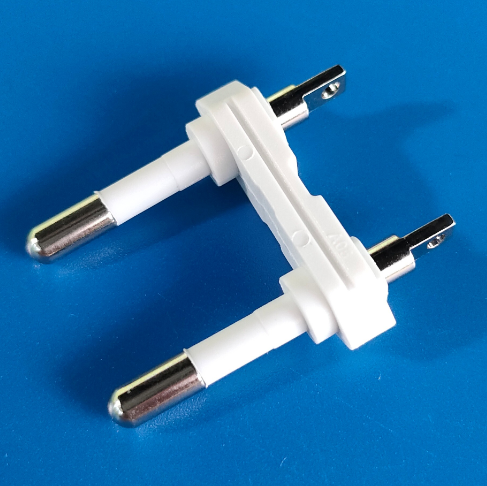

Insert Molding

Insert molding is the innovative solution for seamless integration! With Insert Molding, you can effortlessly combine different materials, creating a sturdy and functional product that meets your specific needs.Our cutting-edge technology allows for the insertion of various components, such as metal or plastic, into the mold during the molding process. This ensures a secure and reliable bond, eliminating the need for additional assembly steps

Metal Precision Casting

Precision casting refers to the general term for the process of obtaining precision-sized castings. Compared with the traditional sand casting process, the castings are obtained by precision casting have more precise dimensions and better surface finish. Its products are precise, complex, and close to the final shape of the part. Can be used directly without processing or processing.It is an advanced process of near-net-shape.